Danish wind turbine manufacturer, Vestas Wind Systems A/S (Vestas), develops and manufactures wind power systems for customers around the globe. Vestas’s products allow customers to replace more carbon-intensive forms of electricity generation with clean wind energy. The company also pays strict attention to its own carbon footprint, using Life Cycle Assessments (LCAs) to measure the environmental impact of its products and services.

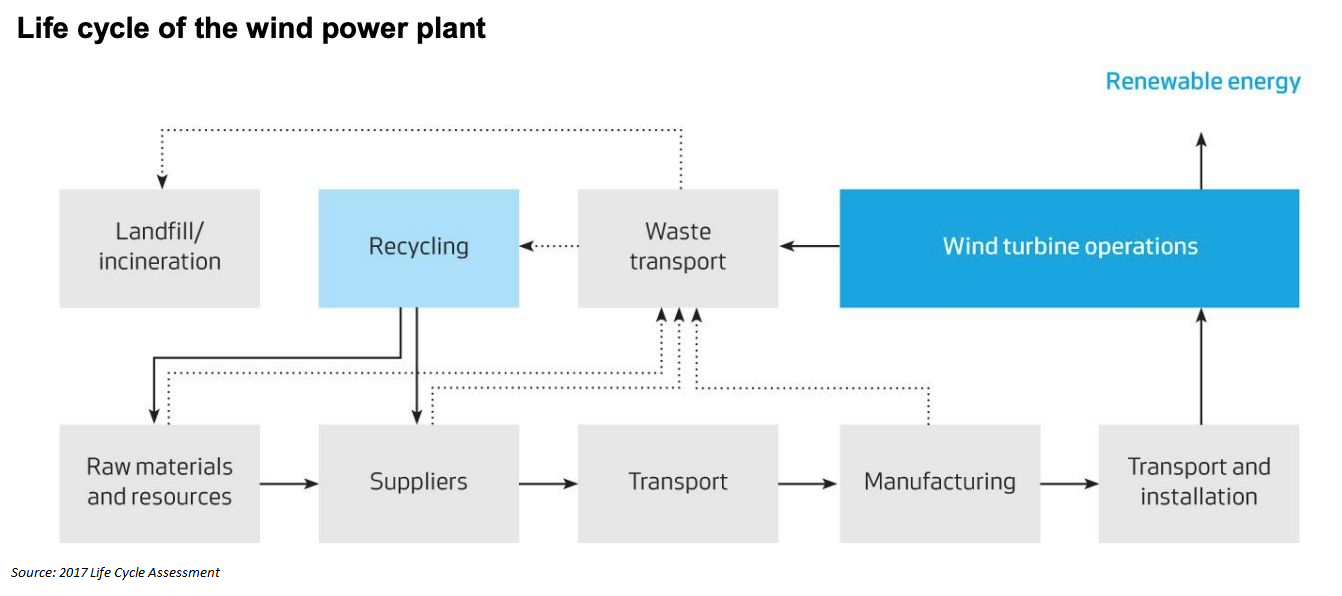

Over time, Vestas has developed a robust framework to improve its wind turbines’ life-cycle circularity. In this context, circularity refers to extending the use of products, by sourcing feedstock from reused or recycled parts, keeping products in use longer, reusing/redistributing parts, and recycling materials at end-of-life. This is reflected in Vestas’s ethos of “reduce (repair), re-use, and recycle.”

In order to close the loop on its product portfolio, Vestas utilizes recycled parts in both manufacturing and repair. Vestas does a Life Cycle Assessment Report for each of its turbine models. The assessment begins at manufacture and continues through the operational phase. It also includes the turbines’ end-of-life dismantling, when its components are either recycled, incinerated with energy recovery, reused, or sent to a landfill. Consider the V136-3.45 MW onshore low-wind turbine. Over its 20-year life, a 100 MW energy plant comprised of V136s will return 32 times more energy than it consumes. The LCA for the V136-3.45 MW notes that 61% of its parts are managed in a circular fashion . Parts made of metal, like the tower and bearings, are both easy to recycle and have a high recycled input content. Blades, which are made of virgin materials, like polymers and glass fibers, are not currently as easy to recycle.

Vestas’s turbine repair solutions allow the company to maximize the value from each turbine’s materials. Vestas’s analysis has shown that using recycled parts for repairs can produce 90% savings in material weight and 95% savings in carbon emissions compared to using a new part. Currently, around 83-89% of a Vestas wind turbine is recyclable, depending on the turbine type. The company has a goal of 100% recyclability of their products across all wind classes. Vestas also monitors 14% of world-wide installed wind capacity, in real time. This enhances the accuracy of LCA measurement and reduces downtime, as gathered data is used to enhance operational efficiency.

Vestas is partnering with the Ellen MacArthur Foundation on circular product design innovation, and its DreamWind project (Designing Recyclable Advanced Materials for Wind Energy) focuses

on developing new sustainable composite materials for turbine blades. Both of these initiatives are moving Vestas closer to its goal of achieving 100% recyclability of its turbines.

Vestas’s LCAs have not only reduced costs for the company but strengthened the value-case of their products. Turbine energy output capacity has increased, without increasing waste. This hard work has paid off with impressive results. Over their life cycle, Vestas’s wind turbines generate 30-50x more energy than they use, and they emit only about 1% of the CO2/kWh that would be emitted if a comparable amount of electricity were generated from coal.